Surface-Mount Technology (SMT) has revolutionized electronics manufacturing by enabling high-density PCB assemblies, faster production cycles, and cost efficiency. However, achieving consistent quality and optimal yield requires careful planning and process optimization. In this article, we outline the top 10 tips to optimize your SMT PCBA production for both prototyping and mass production.

1. Design for Manufacturability (DFM)

The first step to a smooth SMT assembly process is ensuring your PCB design is optimized for manufacturing. Key considerations include:

Proper pad sizes and clearances

Correct solder mask and stencil design

Component orientation and spacing

A well-designed PCB reduces soldering defects, misalignment, and rework. For a deeper understanding of SMT and THT differences in assembly, check out our previous article: SMT vs THT: What’s the Difference and Which Should You Use?

2. Choose Quality Components and Suppliers

Reliable components are critical for reducing defects and improving overall yield. Partner with trusted suppliers who offer:

Verified component authenticity

Adequate stock availability

Consistent quality standards

Ample Chip, as a leading one-stop PCBA service platform, provides high-quality components from major manufacturers, supporting both SMT and THT needs.

3. Optimize Solder Paste Application

Solder paste quality and application directly affect solder joint reliability. Tips include:

Use high-quality, lead-free or compatible solder paste

Ensure stencil thickness matches pad requirements

Maintain proper storage and handling of paste

Correct application reduces tombstoning, bridging, and insufficient soldering.

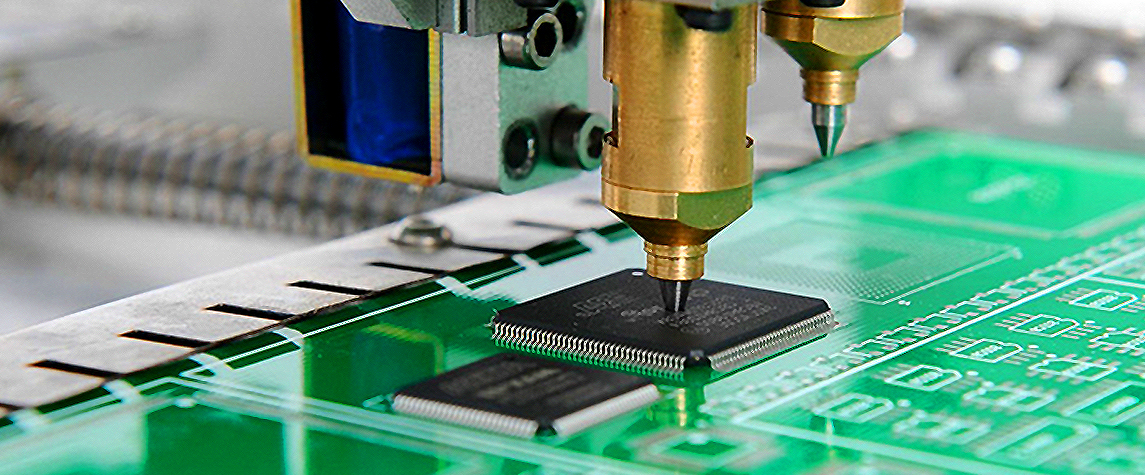

4. Maintain Pick-and-Place Accuracy

Automated pick-and-place machines are the backbone of SMT assembly. Optimize placement by:

Regular calibration of machines

Using vision systems for component alignment

Avoiding excessive vibration and thermal shocks

High placement accuracy ensures consistent soldering and reduces rework.

5. Control Reflow Soldering Profile

Reflow soldering must match the thermal requirements of components and PCB materials. Key steps:

Follow recommended temperature profiles from component datasheets

Monitor peak temperatures to avoid damage

Adjust conveyor speed and zone temperatures as needed

Proper reflow soldering prevents solder voids, lifted pads, and component damage. For more insights on the entire PCBA manufacturing process, see: The Complete PCBA Manufacturing Process Explained

6. Implement Rigorous Quality Inspection

Quality inspection is vital to detect defects early. Recommended methods:

SPI (Solder Paste Inspection): Check solder volume before reflow

AOI (Automated Optical Inspection): Detect misaligned or missing components

X-ray inspection: Check hidden solder joints like BGAs

A robust inspection process reduces returns, scrap, and post-production troubleshooting.

7. Optimize Component Placement Sequence

Efficient component placement minimizes errors and production time. Consider:

Placing large or heat-sensitive components first

Sequencing components to reduce head movement

Grouping similar components together

This approach improves production speed and reduces machine downtime.

8. Maintain Environmental Controls

Temperature, humidity, and cleanliness affect soldering and component reliability. Tips:

Maintain PCB and component storage at recommended conditions

Use dehumidifiers and clean rooms for sensitive components

Avoid electrostatic discharge (ESD) by following proper grounding protocols

Environmental control enhances assembly consistency and product longevity.

9. Invest in Skilled Workforce and Training

Even with automated SMT lines, skilled operators are essential for:

Machine setup and calibration

Manual soldering or rework of small components

Troubleshooting and process improvement

A well-trained team reduces errors, shortens production cycles, and maintains high-quality standards.

10. Adopt Continuous Process Improvement

Regular monitoring and process optimization help sustain efficiency. Steps include:

Collect production data for analysis

Identify recurring defects and root causes

Update DFM guidelines and process parameters accordingly

Continuous improvement fosters higher yield, lower costs, and faster time-to-market.

Conclusion

Optimizing SMT PCBA production requires a balance of design, material quality, process control, and skilled workforce. By following these top 10 tips, electronics manufacturers can achieve faster turnaround, higher yields, and consistent product quality.

For a complete overview of SMT and PCBA services, consider our full One-Stop PCBA Service Platform, which integrates component sourcing, SMT/THT assembly, and rapid prototyping.

Related News

Top 10 Tips to Optimize Your SMT PCBA Production

SMT vs THT: What’s the Difference and Which Should You Use?

What Is SMT Assembly? A Complete Guide

Why Choose Ample Chip for PCB-SMT Support

One-Stop Solution for PCBA: From Component Sourcing to Assembly

PCBA vs PCB vs SMT: What’s the Difference?

The Complete PCBA Manufacturing Process Explained