In the fast-paced world of electronics manufacturing, terms like PCB, PCBA, and SMT are often used interchangeably — but they actually refer to distinct and crucial parts of the electronics production process. Whether you're an engineer, product manager, startup founder, or procurement officer, understanding these terms can help you communicate effectively, avoid confusion, and make better decisions.

What Is a PCB? (Printed Circuit Board)

A PCB, or Printed Circuit Board, is the bare board that provides the foundation for all modern electronics. It’s typically made from a non-conductive substrate (like FR4 fiberglass) and features copper traces that connect various points on the board to form an electrical circuit.

Key features of a PCB:

No components are mounted — it’s just the physical and electrical structure.

Comes in different layers (single, double, or multi-layer).

Includes pads, vias, traces, and sometimes printed labels.

Covered with solder mask and silkscreen for protection and labeling.

In short, the PCB is like the "skeleton" of an electronic device — necessary, but not functional on its own.

What Is PCBA? (Printed Circuit Board Assembly)

PCBA, or Printed Circuit Board Assembly, refers to the fully assembled PCB — that is, a PCB with all the electronic components soldered onto it. These components may include resistors, capacitors, diodes, ICs (Integrated Circuits), connectors, and more.

PCBA is the finished product that can be installed into an electronic device.

Key features of a PCBA:

Includes both active (like ICs, transistors) and passive (like resistors, capacitors) components.

Created using assembly processes like SMT and/or THT (Through-Hole Technology).

Undergoes functional testing to ensure it works as intended.

Can be produced for prototyping, low-volume, or mass production.

In short:

PCB = empty board

PCBA = working circuit board

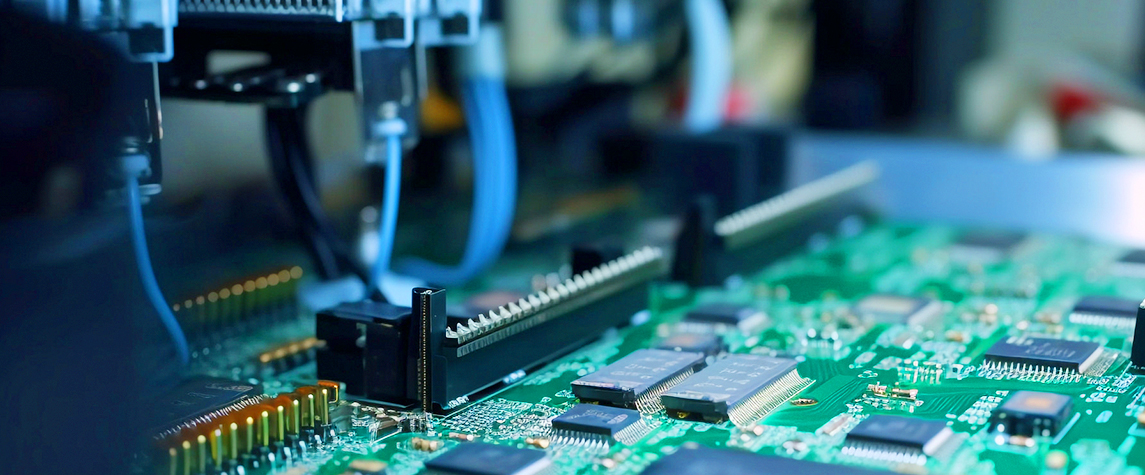

What Is SMT? (Surface Mount Technology)

SMT, or Surface Mount Technology, is a manufacturing method used to assemble components onto a PCB. It’s the most commonly used process in PCBA today, replacing traditional through-hole soldering for most small components.

How SMT works:

Solder paste is applied to the component pads on the PCB using a stencil.

Pick-and-place machines place tiny components (SMDs) onto the board.

The board goes through a reflow oven to melt the solder paste and bond the components.

SMT enables high-speed, automated, and high-density assembly, making it ideal for modern devices like smartphones, laptops, and IoT products.

Summary: Comparing PCB, PCBA, and SMT

|

Term |

Full Form |

Description |

Stage in Process |

|

PCB |

Printed Circuit Board |

Bare board without any components |

Design & Fabrication |

|

PCBA |

Printed Circuit Board Assembly |

PCB with all components mounted |

Final Product Assembly |

|

SMT |

Surface Mount Technology |

Method used to place components on PCB |

Assembly Process (Part) |

How They Work Together

The process typically goes like this:

PCB Design – Engineers design the PCB layout using CAD software.

PCB Fabrication – The blank PCBs are manufactured.

SMT Assembly – Components are mounted on the board using SMT (and sometimes THT).

PCBA Testing – The assembled board is tested for function, performance, and quality.

PCBA Delivery – The final assembled board is sent to customers or installed in a larger product.

So, SMT is part of the assembly method, PCB is the physical base, and PCBA is the final, usable product.

Why This Matters

Understanding the differences is important for:

Clear communication between engineers, manufacturers, and procurement.

Accurate quoting: PCBs are cheaper than PCBAs; SMT affects cost and speed.

Product development timelines: Knowing the steps involved helps plan better.

Avoiding misunderstandings: For example, ordering a “PCB” when you really need a “PCBA” could delay your project significantly.

If you're sourcing for a prototype or mass production, being specific about whether you need just PCBs or assembled PCBAs with SMT is critical.

Ample Chip: Your One-Stop PCB, PCBA & SMT Partner

At Ample Chip, we specialize in more than just electronic components — we provide end-to-end services from PCB fabrication, component sourcing, SMT assembly, to complete PCBA delivery.

As a leading independent agent and distributor of semiconductors and electronic components, Ample Chip supports OEMs, EMS providers, hardware startups, and R&D teams across the globe.

Why choose Ample Chip?

High-speed SMT lines for fast, precise assembly

Reliable PCB fabrication, including multilayer, HDI, and flexible boards

Verified component sourcing from trusted brands

One-stop PCBA services from sample to mass production

24-hour turnaround for urgent projects

Strict quality control and functional testing

Whether you're prototyping a new device or scaling production, Ample Chip offers the speed, quality, and supply chain efficiency you need to succeed in today's competitive market.

Related News

One-Stop Solution for PCBA: From Component Sourcing to Assembly

PCBA vs PCB vs SMT: What’s the Difference?

What Is the Difference Between PCBA and PCB?

Why Choose Ample Chip for PCB-SMT Support