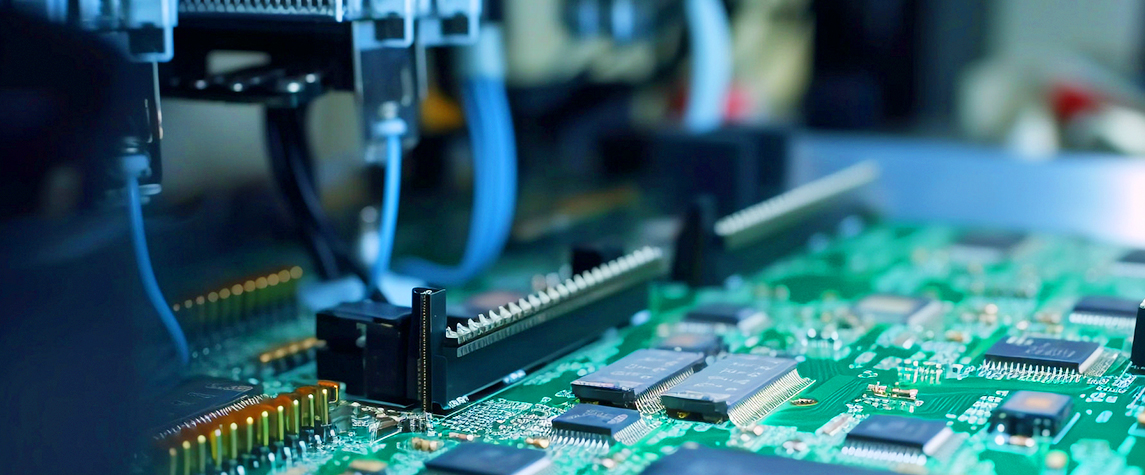

In the fast-paced world of electronics manufacturing, efficiency, reliability, and cost control are essential for staying competitive. Printed Circuit Board Assembly (PCBA) is at the core of this industry, serving as the backbone for consumer electronics, medical devices, industrial control systems, and communication equipment. However, many businesses face challenges in managing the complex process of PCBA—from sourcing components to final assembly. A one-stop PCBA solution addresses these pain points, enabling companies to streamline operations, improve product quality, and shorten time-to-market.

Understanding the One-Stop PCBA Solution

A one-stop PCBA solution refers to a comprehensive service model in which a single supplier provides end-to-end support, including:

Component Sourcing – Finding reliable, authentic, and cost-effective electronic components from global suppliers.

PCB Manufacturing – Designing and producing printed circuit boards in various forms, including single-sided, double-sided, multi-layer, flexible, and HDI boards.

Assembly Services – Performing both surface mount technology (SMT) and through-hole assembly with advanced equipment and strict quality checks.

Testing & Quality Assurance – Ensuring the finished boards meet international standards through rigorous inspection and testing.

Logistics & Delivery – Offering efficient packaging, warehousing, and shipping solutions to get the final product to market quickly.

This integrated model eliminates the need for multiple vendors and allows companies to work with a single, trustworthy partner throughout the entire PCBA process.

Key Benefits of the One-Stop PCBA Model

1. Cost Efficiency

When companies rely on multiple suppliers, the risk of hidden costs increases—such as price fluctuations, duplicate shipping fees, and additional management overhead. A one-stop PCBA supplier consolidates these steps, reducing unnecessary expenses and providing a more transparent pricing structure.

2. Quality Control and Reliability

In electronics, even one faulty component can lead to product failures or recalls. A professional one-stop PCBA partner implements strict incoming material inspections, in-process testing, and final quality checks. This ensures that every circuit board meets required industry standards such as ISO, RoHS, or IPC.

3. Time Savings

Speed is critical in industries like consumer electronics and communication technology. Managing multiple vendors often leads to delays due to miscommunication or logistics issues. A one-stop solution allows for streamlined communication, faster decision-making, and reduced lead times—helping products reach the market ahead of competitors.

4. Supply Chain Stability

Global supply chain disruptions have highlighted the risks of depending on scattered vendors. A reliable PCBA supplier with established sourcing channels can secure essential components even during shortages. This helps manufacturers avoid costly production halts.

5. Technical Support and Customization

Modern electronics are becoming more complex, requiring advanced assembly techniques such as BGA, QFN, or fine-pitch component placement. A one-stop PCBA supplier typically offers engineering support, design-for-manufacturability (DFM) reviews, and custom assembly solutions to meet specific technical requirements.

Application Across Industries

The advantages of one-stop PCBA services extend across a variety of sectors:

Consumer Electronics – Smartphones, tablets, and smart home devices rely on compact, high-density PCBAs that require precision assembly.

Automotive Electronics – Advanced driver-assistance systems (ADAS), infotainment units, and EV control systems demand highly reliable boards with rigorous testing.

Medical Equipment – From portable diagnostic devices to advanced imaging machines, the accuracy and safety of PCBA is mission-critical.

Industrial Control Systems – Machinery, robotics, and factory automation require durable and long-life PCBAs that can withstand harsh environments.

Telecommunication and Networking – 5G base stations, routers, and IoT devices depend on high-performance PCBAs with stable connectivity.

By offering one-stop PCBA solutions, suppliers ensure that industry-specific requirements are met without compromise.

How to Choose the Right One-Stop PCBA Supplier

Selecting a PCBA partner is a strategic decision that impacts product performance and business success. Here are some key factors to consider:

Experience and Expertise – Look for suppliers with proven experience in diverse industries and complex assembly projects.

Component Sourcing Network – Ensure the supplier has access to global distributors and original manufacturers for authentic, traceable parts.

Quality Certifications – Compliance with ISO9001, IATF16949, or IPC standards indicates a commitment to quality and reliability.

Scalability – The supplier should handle both prototype orders and large-scale production runs with the same level of professionalism.

Customer Support – Technical support, responsive communication, and after-sales service are crucial for long-term partnerships.

Conclusion

The one-stop PCBA solution represents a smarter and more efficient way for businesses to handle the increasingly complex demands of electronics manufacturing. By consolidating component sourcing, PCB production, assembly, and quality assurance under one roof, companies can significantly reduce costs, save time, and ensure product reliability.

For organizations seeking a trusted partner, Ample Chip stands out as a leading PCBA wholesale supplier. With a strong global sourcing network, advanced production capabilities, and a commitment to delivering high-quality solutions, Ample Chip helps clients bring their ideas to life with speed and precision. Whether for consumer electronics, automotive, medical, or industrial applications, Ample Chip is your reliable partner in the world of PCBA manufacturing.

Related News

One-Stop Solution for PCBA: From Component Sourcing to Assembly

PCBA vs PCB vs SMT: What’s the Difference?