In the world of electronics manufacturing, selecting the right assembly method is crucial for cost, performance, and reliability. Two primary methods dominate the printed circuit board assembly (PCBA) process: Surface-Mount Technology (SMT) and Through-Hole Technology (THT). Understanding their differences, advantages, and limitations can help engineers, product developers, and procurement teams make informed decisions for every project.

1. What Is SMT (Surface-Mount Technology)?

Surface-Mount Technology (SMT) involves mounting electronic components directly onto the surface of a printed circuit board (PCB). Components are typically small, lightweight, and designed with flat leads or contacts.

Common SMT components include:

Resistors, capacitors, and inductors

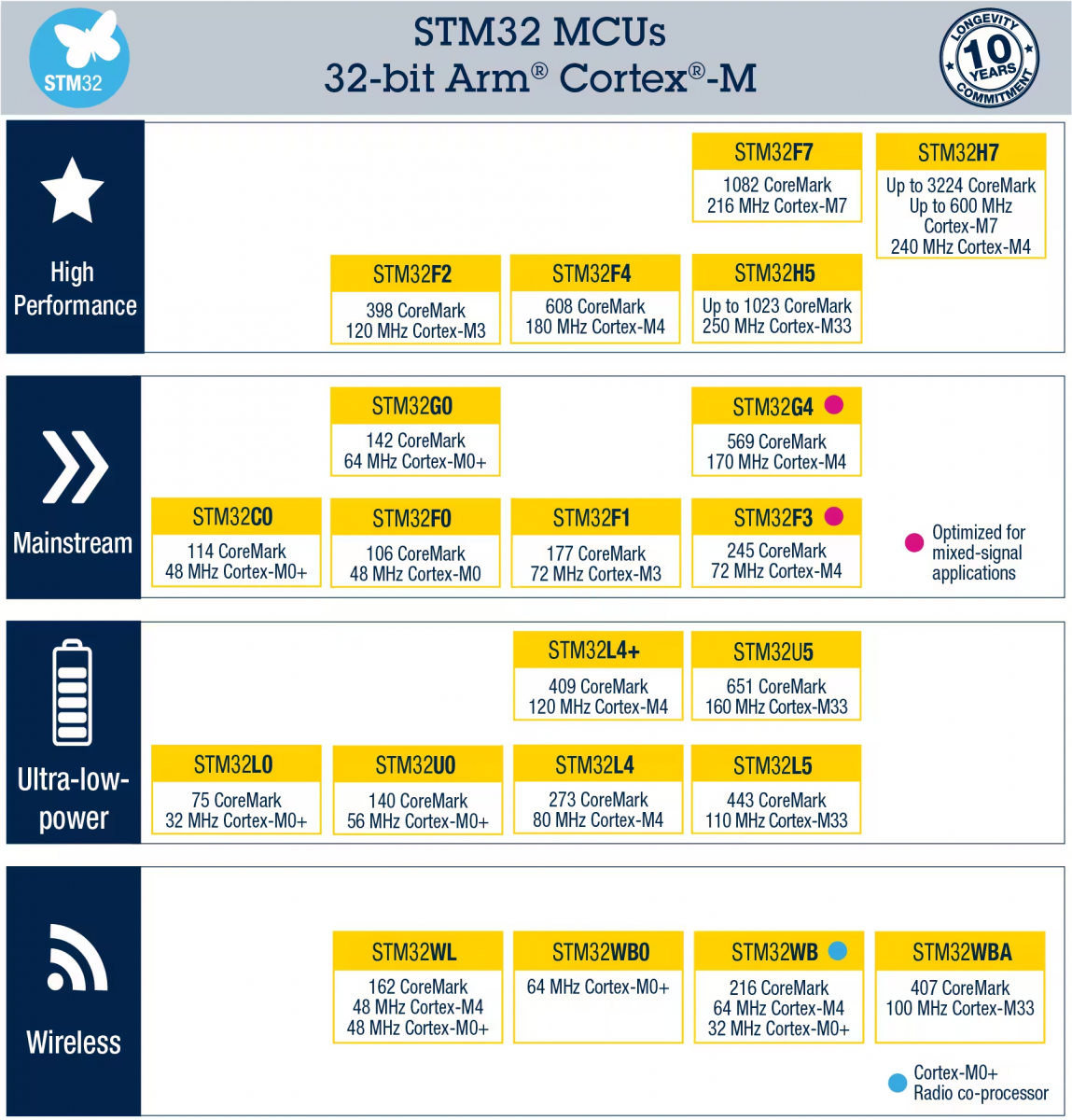

Integrated circuits (ICs) such as microcontrollers and processors

LEDs and small connectors

BGA, QFN, LGA packages

Advantages of SMT:

Compact design: Allows high-density PCB layouts, enabling smaller and thinner devices.

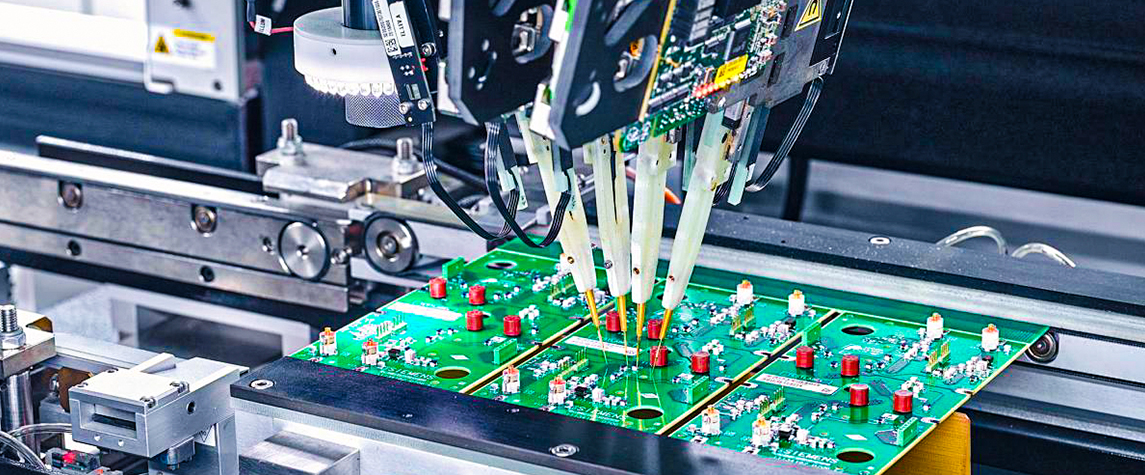

High-speed assembly: Automated pick-and-place machines can place thousands of components per hour.

Cost-effective for mass production: Lower labor costs and less drilling.

Enhanced electrical performance: Shorter lead lengths reduce parasitic inductance and resistance.

Limitations of SMT:

Limited mechanical strength for high-stress applications (vibration, heavy components).

Difficult to manually solder or repair small components (01005, 0201).

May require specialized inspection equipment like AOI or X-ray for quality assurance.

2. What Is THT (Through-Hole Technology)?

Through-Hole Technology (THT) involves inserting component leads into pre-drilled holes on the PCB and soldering them either manually, by wave soldering, or selective soldering. This method has been used for decades and is ideal for certain types of components and applications.

Common THT components include:

Large capacitors and inductors

Connectors and switches

Transformers and relays

Power transistors

Components that must endure mechanical stress

Advantages of THT:

Strong mechanical connection: Ideal for boards that experience vibration, stress, or repeated use.

Ease of manual assembly and repair: Suitable for prototyping and low-volume production.

Higher current and power handling: Leads can carry more current and dissipate heat efficiently.

Limitations of THT:

Slower assembly process compared to SMT.

Larger board space required for components and holes.

Higher drilling and material costs.

Limited suitability for high-density or miniaturized designs.

3. Key Differences Between SMT and THT

|

Feature |

SMT (Surface-Mount) |

THT (Through-Hole) |

|

Component Placement |

On the PCB surface |

Inserted into drilled holes |

|

Assembly Method |

Pick-and-place automation |

Manual, wave, or selective soldering |

|

Mechanical Strength |

Moderate |

High, ideal for stress-prone boards |

|

Board Density |

High, supports miniaturization |

Lower, larger spacing required |

|

Cost |

Lower for mass production |

Higher due to drilling and labor |

|

Inspection |

AOI, X-ray |

Visual inspection, manual testing |

|

Applications |

Smartphones, laptops, IoT, high-speed circuits |

Power electronics, connectors, industrial, automotive |

4. When to Use SMT vs THT

The choice between SMT and THT depends on multiple factors:

Use SMT when:

PCB requires high component density and compact design

Production is automated and high-volume

Cost reduction is important

Signal integrity or high-frequency performance is critical

Use THT when:

Components are large, heavy, or mechanically stressed

Prototyping or low-volume production is needed

Reliability and durability under vibration or thermal cycling are essential

High current carrying capacity is required

Mixed Technology (SMT + THT)

Many modern PCBs combine both technologies. For example:

SMT for most small ICs and passive components

THT for connectors, power transistors, or components requiring mechanical stability

This approach balances performance, space efficiency, and reliability.

5. Advantages of a Professional SMT & THT PCBA Service

Working with a reliable PCBA manufacturer, like Ample Chip, ensures:

Advanced SMT lines capable of 0201 / 01005 components

Precise THT insertion and selective soldering

Quality control with SPI, AOI, X-ray, ICT, and FCT testing

Fast prototyping and mass production turnaround

Component sourcing from trusted suppliers with full traceability

Choosing a partner with both SMT and THT capabilities allows flexible solutions for consumer electronics, automotive electronics, industrial control systems, and medical devices.

6. Conclusion

Understanding the differences between SMT and THT is crucial for optimal PCB assembly decisions. While SMT excels in miniaturization, automation, and cost-effectiveness, THT provides mechanical strength and durability. In most modern electronics, a mixed approach is the best solution, leveraging the benefits of both technologies.

By working with a professional one-stop PCBA service provider like Ample Chip, designers and engineers can achieve reliable, high-quality assemblies tailored to the requirements of any application—be it high-density consumer devices or robust industrial systems.

Related News

What Is SMT Assembly? A Complete Guide

Why Choose Ample Chip for PCB-SMT Support

One-Stop Solution for PCBA: From Component Sourcing to Assembly

PCBA vs PCB vs SMT: What’s the Difference?

The Complete PCBA Manufacturing Process Explained