Ideal for PCBA beginners, engineers, sourcing teams, and procurement managers

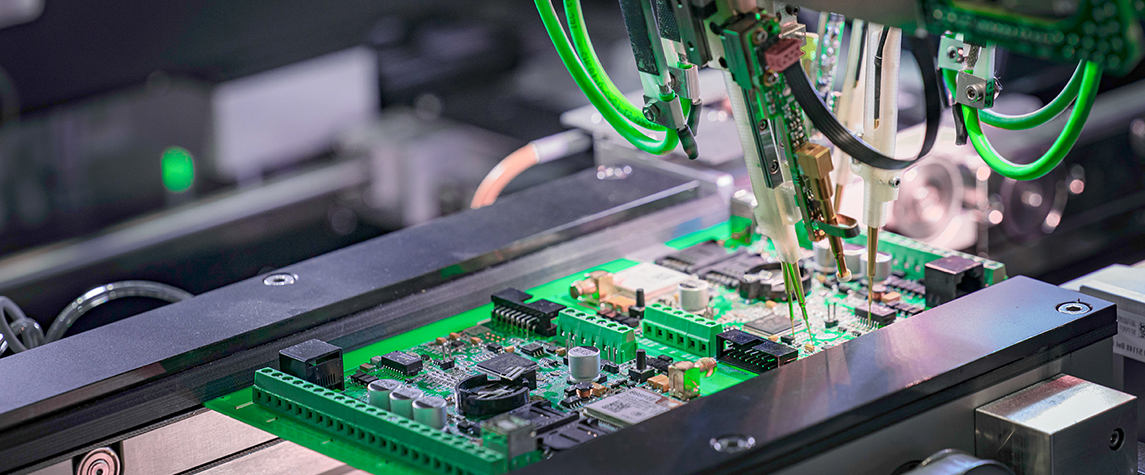

Surface Mount Technology (SMT) has become the foundation of modern electronics manufacturing. From smartphones and IoT sensors to industrial controllers and medical devices, nearly every electronic product today relies on SMT assembly for its compact size, high performance, and manufacturing efficiency.

If you are new to electronics production, understanding SMT assembly will help you make better decisions when selecting manufacturers, controlling product quality, and accelerating your development cycle.

This guide explains what SMT is, how the SMT process works, why it matters, and how companies like Ample Chip deliver high-speed and high-reliability SMT services.

1. What Is SMT Assembly?

SMT Assembly (Surface Mount Technology Assembly) is the process of placing electronic components directly onto the surface of a PCB (Printed Circuit Board). Instead of inserting leads into drilled holes—like in traditional THT (Through-Hole Technology)—SMT relies on solder paste and reflow soldering to secure components.

Key Characteristics of SMT:

No holes required → allows for dense component placement

Supports very small components (e.g., 01005, 0201 size)

Enables high-speed, automated production

Reduces cost and improves manufacturing efficiency

Because SMT creates lighter, smaller, and more complex PCB assemblies, it has become the global standard for electronics production.

2. Why SMT Replaced Traditional Through-Hole Assembly

While THT is still used for special components (connectors, transformers, relays), SMT dominates for three major reasons:

a. Miniaturization

Modern electronics demand extremely small components. SMT supports micro-sized parts like resistors, capacitors, ICs, BGAs, and QFNs.

b. Higher Circuit Density

No drilling means more space for routing, enabling multi-layer and HDI PCB designs.

c. Faster & Cheaper Production

SMT pick-and-place machines can mount tens of thousands of components per minute, dramatically reducing labor and assembly costs.

This is why nearly all compact consumer products rely heavily on SMT.

3. The SMT Assembly Process: Step-by-Step Explained

Below is the complete SMT manufacturing workflow used in professional PCBA factories like Ample Chip.

Step 1: Solder Paste Printing

Using a stainless-steel stencil, solder paste is printed onto the PCB pads with high precision.

Key requirements:

Proper stencil thickness (typically 100–150 μm)

Uniform paste distribution

Clean edges to prevent solder bridging

Step 2: SPI (Solder Paste Inspection)

A 3D SPI machine checks:

paste height

paste width

volume

alignment

If solder paste deposit is incorrect, the SMT line will stop automatically to avoid defects downstream.

Step 3: High-Speed SMT Component Placement

Pick-and-place machines place components onto the PCB with speeds up to 50,000–80,000 CPH (components per hour).

Common SMT components:

Resistive & capacitive chips (R/C)

ICs and microcontrollers

QFP / QFN

BGA / LGA

Sensors, oscillators, LEDs

Ample Chip's lines support:

01005 ultra-small components

Fine-pitch ICs

High mix / low volume production

Large-scale mass production

Step 4: Reflow Soldering

Boards then enter a multi-zone reflow oven, where solder melts and bonds components to the PCB.

A proper reflow profile includes:

Preheat

Soak

Reflow (liquidus)

Cooling

Any deviation may cause:

tombstoning

cold solder joints

solder voids

component misalignment

Step 5: AOI Inspection

Automated Optical Inspection checks:

missing parts

wrong polarity

solder bridges

insufficient solder

incorrect placement

High-quality PCBA manufacturers use AOI after every SMT line.

Step 6: X-Ray Inspection (for BGA / QFN)

Hidden solder joints under BGAs cannot be inspected visually.

X-ray detects:

solder voids

bridging under the chip

insufficient solder balls

Step 7: Rework & Manual Inspection

Complex components may require fine soldering by certified technicians.

Step 8: Functional Testing (FCT)

To ensure the PCBA works as intended, FCT simulates actual working conditions:

power on testing

signal integrity testing

program burning

ICT / flying probe testing

4. Advantages of SMT Assembly

a. Smaller Product Size

Critical for IoT devices, wearables, medical sensors, smartphones.

b. Lower Manufacturing Cost

Less drilling, faster automation, fewer manual steps.

c. Better Electrical Performance

Shorter interconnects → lower inductance → improved signal integrity.

d. Higher Reliability

Reflow soldering creates stronger connections compared to manual solder.

e. High-Speed Production

Ideal for large-volume electronics manufacturing.

5. Common SMT Defects and How Manufacturers Avoid Them

1. Tombstoning

Caused by uneven solder paste or temperature imbalance.

2. Bridging

Pads too close, excessive solder.

3. Insufficient Solder

Stencil thickness mismatch.

4. Misalignment

Caused by inaccurate placement or improper PCB design.

5. BGA Voids

Fixed with controlled reflow profiles and X-ray inspection.

Professional factories like Ample Chip minimize defects through:

DFM checks

SPI + AOI

X-ray for hidden joints

Strict quality control

6. SMT Assembly Applications Across Industries

SMT is essential for:

Consumer Electronics

Smartphones, tablets, cameras, audio devices

Industrial Electronics

PLC, control boards, industrial sensors

Medical Devices

ECG monitors, wearable medical sensors, diagnostic equipment

Automotive Electronics

ADAS, EV battery management, dashboards, control units

Telecom & Networking

Routers, base stations, antennas, IoT gateways

LED Lighting

Drivers, COB modules, LED panels

7. Choosing the Right SMT Assembly Manufacturer

When selecting an SMT partner, check for:

Certification (ISO 9001, ISO 13485, IATF 16949)

Equipment (high-speed SMT machines, reflow with precise control)

Testing capabilities (AOI, X-ray, FCT)

Component sourcing ability

Lead time for prototypes & mass production

Ample Chip offers:

High-speed SMT assembly

24-hour quick-turn PCBA prototyping

One-stop service including BOM sourcing, PCB fabrication, and testing

Small-batch and large-batch production

8. Final Thoughts

SMT assembly is the backbone of modern electronics manufacturing.

Whether you are building an IoT device, industrial controller, or medical-grade equipment, choosing the right SMT partner ensures faster production, lower costs, and higher reliability.

With advanced SMT lines, strict quality control, and rapid prototyping capabilities, Ample Chip provides a complete one-stop solution for all PCBA manufacturing needs.

Related News

What Is SMT Assembly? A Complete Guide

Why Choose Ample Chip for PCB-SMT Support

One-Stop Solution for PCBA: From Component Sourcing to Assembly

PCBA vs PCB vs SMT: What’s the Difference?

The Complete PCBA Manufacturing Process Explained